IKING GROUP-INSULATION AND ACOUSTIC SOLUTION FOCUS

The importance of a well-insulated home can’t be overstated: Properly sized and installed insulation can reduce energy usage, keep you warmer in winter and cooler in summer, and save you money with lower energy bills.For homeowners and homebuilders alike, fiberglass insulation has been the insulation of choice for many decades. While fiberglass remains very popular, there’s a relatively new type of insulation that’s making headway—and headlines—in the insulation industry. It’s called rock-wool insulation.

What Is Rock Wool Insulation?

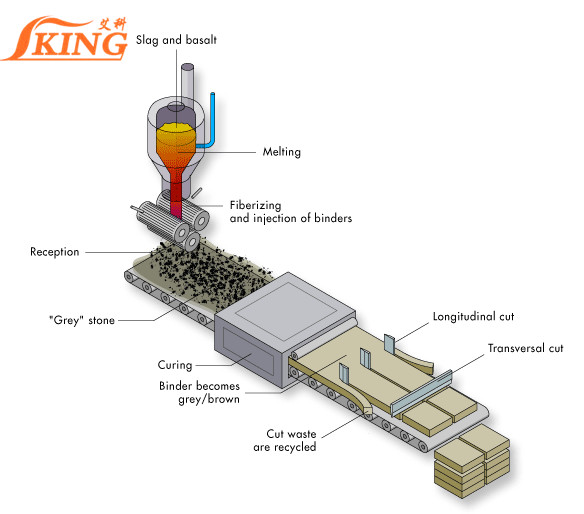

Rock wool, which is also called mineral wool, comes in easy-to-install batts, similar to fiberglass. But instead of being composed of fluffy glass fibers, rock wool is made of—you guessed it—rocks, which doesn’t even seem possible. Here’s a brief explanation of the manufacturing process.

Natural rock is heated in a furnace to about 3,000 degrees until it melts into a liquid. The magma-like liquid is exposed to a high-pressure jet of air or steam, and then spun at super-high speed into long fiber strands. (Think: cotton candy machine filled with liquid rock.) The strands are captured and compressed into thick, dense mats, which are then cut into convenient-sized batts of insulation.

The unique composition of rock wool produces a high-performing insulation with the following features:

1.Made from natural, sustainable material

2.Typically contains up to 75 percent recycled content

3.Retains heat well and traps air, which slows the transfer of heat

4.Non-combustible and fire resistant to about 1,400 degrees

5.Highly water repellent

6.Excellent sound-deadening properties

7.Higher insulating value than fiberglass

8.Long-term performance—rock wool doesn’t degrade over time

9.Allows moisture to escape (which deters mold and mildew)

10.Dense, firm batts are friction-fit into place; no stapling necessary

Where to Use Rock Wool Insulation

Rock-wool insulation can be installed wherever you’d install fiberglass or any other type of insulation, including walls, floors, ceilings, attics and crawlspaces. However, it’s particularly well-suited for rooms along the cold north side of the house and for interior rooms in need of sound deadening, such as media rooms or music studios.

Because rock wool is highly fire resistant, it’s ideal—and often code-required—for use as a firestop between floors of a house. (During remodeling or new construction, ask the local building inspector to identify specific areas that require rock wool firestops.)

Rock wool is also easy to work with: The firm batts can be cut with a serrated knife or handsaw to fit snugly into place. If it gets wet, water beads up and rolls off without soaking into the fibers. The rock-wool fibers are compacted so tightly together that there’s no chance of the insulation shifting out of position or slumping down, which would dramatically decrease its insulating value.