IKING GROUP-INSULATION AND ACOUSTIC SOLUTION FOCUS

Mineral wool has some real advantages over the alternatives. If you have an insulation job coming up, we strongly recommend that you check it out.

What's the difference between mineral wool insulation and fiberglass?

When most people think insulation, they think fiberglass. It is definitely the most common and is widely used in jobsites across the country. Mineral wool insulation is decidedly less common, despite the fact that this insulation has been around for decades, is widely used in Canada and Europe, and is making a comeback in the United States. It is made by melting down basalt stone and recycled slag from steel mills, which is then spun into fiber that can be formed into batts or boards.

We wanted to know more so we did some research, talked to installers, and filled a few walls with the stuff. Here’s our verdict: Mineral wool insulation has some real advantages over the alternatives.

Installation of mineral wool insulation

Turns out, it is much easier to do a top-notch insulation job if you use mineral wool instead of fiberglass.

Because of its greater rigidity, mineral wool insulation can be easily and simply slid into the space between studs. By contrast, fiberglass batts simply aren’t easy to install accurately. They’re floppy, don't stick together and are prone to overstuffing. Next, learn the differences between pink, yellow and green insulation here.

Carve it up

Mineral wool insulation batts are so dense that you can carve them to accurately fit around outlets and other obstacles. Just measure and mark like you would if you were making a drywall cutout. This works for outlets, pipes or any other obstruction you’re likely to run into.

Mineral wool insulation is easy to measure

Measuring fiberglass insulation accurately is not fun. It tears, scrunches up and when you try to corral the material it can make you very, very itchy. Mineral wool batts, in contrast, is very easy to measure. It's rigid form just sits there, unmoving, so you can quickly whip out your tape and get an accurate measurement.

Fire and water resistance

Mineral wool insulation withstands extreme heat better than other types of insulation. In a fire, the batts retain their shape and offer better protection against flame spread. And you builders may be interested to learn that when they’re combined with special fire-rated sheathing, mineral wool batts can be used to create a one-hour-fire-rated assembly without any extra labor.

Another cool property of mineral wool batts is that they don’t absorb water, staying intact even when wet. This means that if your wall or roof leaks, the batts will be as good as new after they dry out. Fiberglass or cellulose, on the other hand, droop, clump up or compress when they get wet. And sometimes, the only way to restore their insulating value is to tear off the wall covering and replace them. When it comes to water resistance, only foam insulation beats mineral wool.

Sound proofing

Mineral wool insulation batts are denser than other types of insulation, making them better at soundproofing interior walls, floors and ceilings. Install batts between rooms or in the joist spaces between floors to reduce sound transmission.

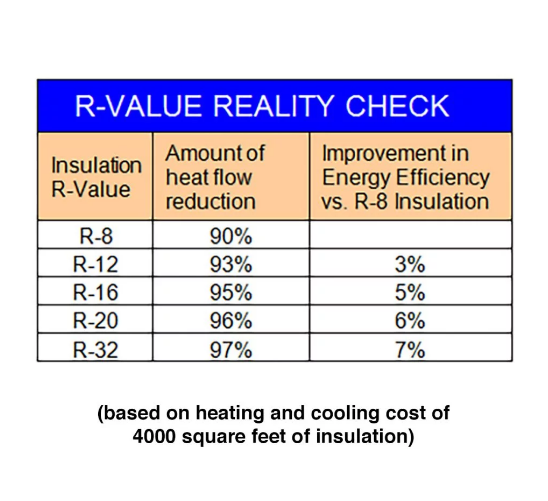

R-value

Mineral wool batts are slightly better insulators than the off-the-shelf fiberglass batts sold at most lumberyards and home centers. Mineral wool batts for 2x4 walls have an R-value of 15, while a standard fiberglass batt made to fit in a 2x4 wall has an R-value of 11 or 13. However, you can special-order R-15 high-density fiberglass batts. (In case you don't know: the larger the R-value, the better insulator the material is.)

Mineral wool batts for 2x6 walls have an R-value of 23, compared with R-19 for fiberglass batts. A 2x4 stud cavity filled with blown-in cellulose has an R-value of about 13.